An Understanding of Crankshaft Position Sensor

A crankshaft position sensor (also known as the CKP) detects when a piston is positioned over the top dead center and helps to keep track of your fuel economy. The most common location for them is right under your gas cap. They are typically found in any vehicle that has an automatic transmission.

They are used to detect when a piston is exactly halfway up its stroke. When this happens, it sends a signal to the computer which adjusts your fuel mixture accordingly. This improves the efficiency of combustion and can lower emissions by almost 4%.

You might not think much about how this works, but your motor will thank you if you take the time to understand this system. In order to know more about this, read on!

Table of Contents

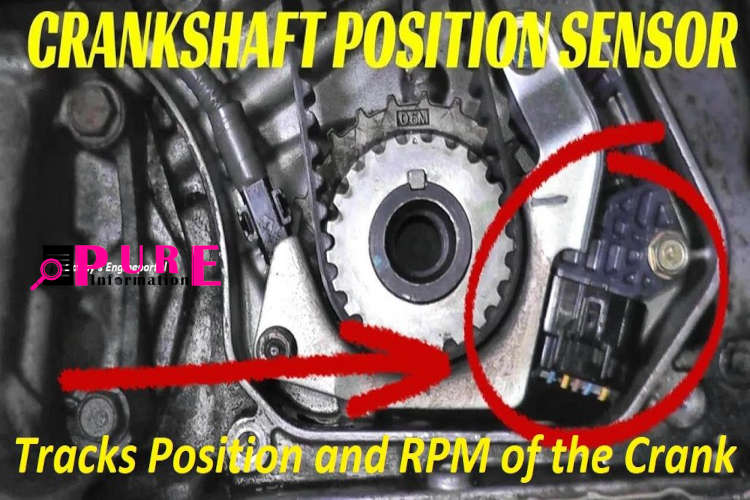

What Is a Crankshaft Position Sensor?

A crankshaft sensor (CKP) is an electronic device that helps your engine control system know when the pistons in the cylinders have reached their top-dead-center positions. This information allows the computer to determine the correct timing for fuel injection, ignition, etc.

There are two different kinds of CKPs: one type detects the position of the piston at the top of the cylinder, while the other detects the position of the piston at the bottom of the cylinder. The first kind of sensor is located in the head of each individual cylinder, and it measures the distance from the center of the spark plug hole to the top of the piston.

This measurement is used by the computer to calculate when the right amount of air/fuel mixture should be injected into the combustion chamber.

The second type of CKP is located near the front of the camshaft, and it measures the distance between the top of the valve stem to the top of the piston.

Types of a Crankshaft Position Sensor

A Crank Shaft Position Sensor (CSS) is an electronic device that senses the position of the camshaft relative to the timing chain. The CSS provides information to the engine management computer regarding when the camshaft should be rotated in relation to the crankshaft so that the correct mixture of fuel and air can be delivered to each cylinder at precisely the right time.

There are three main categories of CSSs: single-wire, dual-wire and digital. Single-wire sensors use a single electrical conductor to transmit data from the sensor to the ECU. Dual-wire sensors have two conductors, one for transmitting the signal and another for receiving the response from the ECU. Digital sensors work by sending a pulse of electricity through the wires, which are received by a coil in the ECU. This method allows for a much more precise positioning of the shaft.

Signs of a Failing or Bad Crankshaft Position Sensor

If your automobile isn’t running well, you might be curious to read more about the signs of a failed or defective crankshaft position sensor. This component aids in the engine’s rotation. Take your car to the dealer so they can examine the status of this specific component if you are concerned that it isn’t operating as it should.

There are several different signs that you need to look for. The first thing to do is to make sure that the oil level is high enough. You also want to pay attention to how much gas you use. There will always be a little bit of extra fuel, but if you notice that your tank is filling up quickly, then you’ll know that there is a problem with the crankshaft position sensor.

Another sign that you need to worry about is the way that your engine sounds when you start the car. It should sound like it’s turning over smoothly. If not, you may have a problem with this important part.

Don’t Ignore Signs Signaling Possible Issues

If you’re driving your car, you should know that there are certain things that you need to check regularly. For example, when you turn on the ignition, you need to make sure that the engine is working properly. If it’s not, then you’ll have a problem before you get very far.

In addition, you also need to be aware of the oil level in your vehicle. When you start the engine, you should always take note of how much oil you’ve got left. You don’t want to run out of oil while you’re driving down the road.

You also need to monitor the water levels in your radiator and the coolant in your cooling system. This will help ensure that your car is running at peak efficiency.

But what happens if you notice that there are problems with one or more of these areas? What do you do? The best way to deal with this situation is by taking the time to read the owner’s manual. There, you’ll find information on all of the things that you need to pay attention to.

Conclusion

In conclusion, Crankshaft position sensors are very important for your vehicle’s engine to function properly. They measure the engine’s position, which helps it to know when to start and when to stop. If a sensor is damaged, it can cause the engine to run out of fuel, causing damage to the engine. In this website, we’ll show you how to identify a cracked sensor and how to replace it.